Repair Tracking

On-station repairs

Marine Technical Limits (MTL) offers a complete and integrated service to deliver on-station structural repairs while your asset remains in production. We have a proven track record in managing hotwork on deck, in tanks and other confined spaces – including boundary hotwork and hotwork on the side and bottom shell. PYXIS underpins our complete offering and allows us to deliver with consistent success.

End-to-end solution

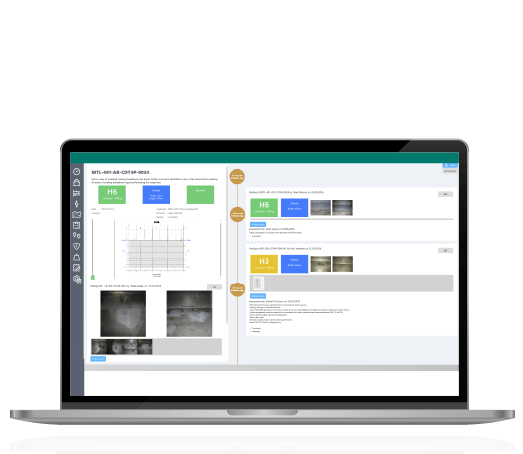

Digital repair definition

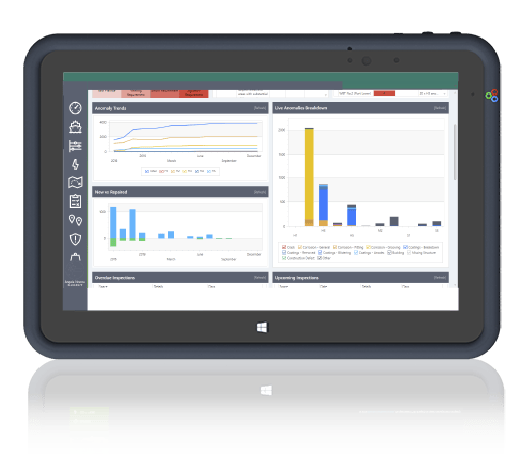

Understanding of class inspections, integrity inspection (from defects) and repair campaigns are all available in a single application. Clear and comprehensive repair definitions are readily accessible. These outline what needs to be done at each location and detail resource requirements, including skills materials and equipment.

Evidence based close out

PYXIS is a central digital repository for close out evidence, enabling efficient collaboration between offshore team and onshore engineers. Data can be easily shared and made available to technical authority and Class.

Why MTL?

- Projects delivered safely, efficiently, on-time and on-budget

- Experienced Naval Architect team with extensive experience of repair campaigns

- All available integrity, inspection and repair data held in one system

- Effective work planning prioritisation based on criticality

- Efficient and cost-effective management of resources

- Comprehensive and transparent repair campaigns

- Web based client interface provides full insight into current and historical data

Priorities and progress

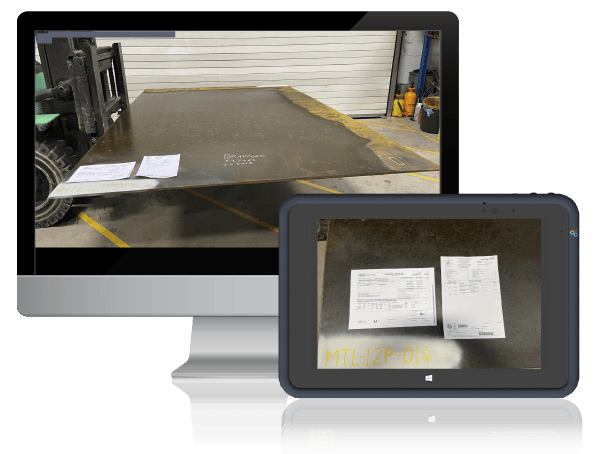

Full material trace-ability

PYXIS delivers unsurpassed quality assurance with full materials traceability. Certification and relevant documentation is stored in the cloud and accessible anywhere on any device.

Get In Touch

Contact us today to see how we can help you.